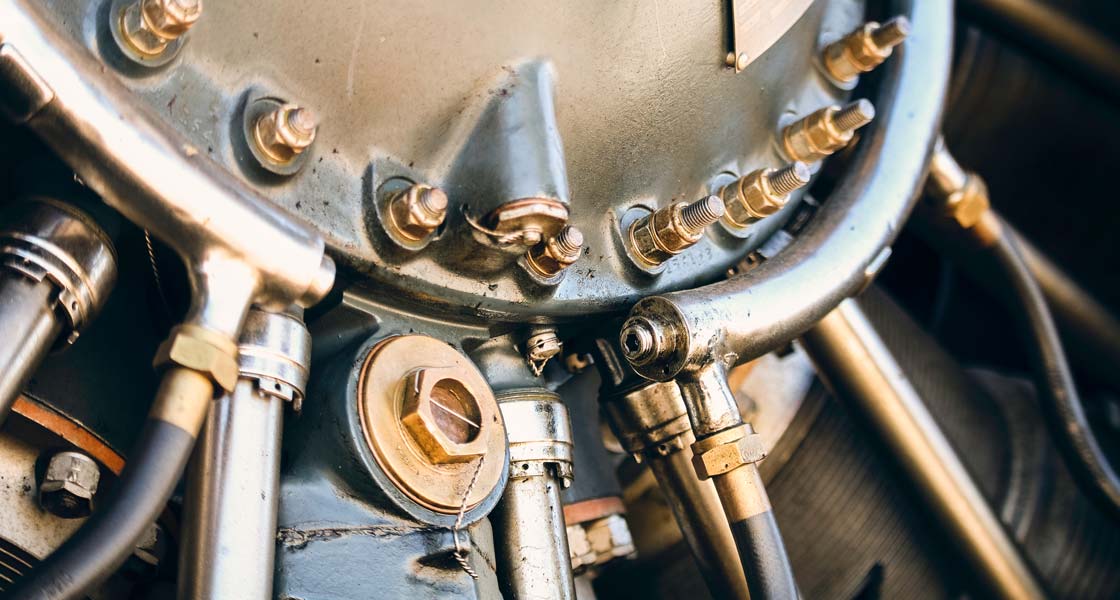

Click on the picture to enlarge

INDUSTRIAL MACHINERY

ASSEMBLY

The main activity of REMP is the assembly for third parties of new industrial machinery and in particular of:

ASSEMBLY PHASES

The assembly phase is carried out following a procedure that allows for precision assembly and in the time required.

The customer has the task of delivering all the disassembled details, documentation, drawings and diagrams related to hydraulic and electric pneumatic systems.

The assembly phases of Remp include:

It is possible to see the complete assembly diagram by clicking on the picture.

INDUSTRIAL MACHINERY

REPAIR

REMP has seen its workshop expertise grow over the past few years, enabling it to carry out repairs and work on industrial machinery.

In fact, the workshop has a lathe, milling cutter, cropper, welding machine, column drills and numerous other devices that allow you to carry out machining, even of precision, in total autonomy.

This is a matter of work, a new customer advantage, the construction of damaged or newly constructed parts is not entrusted to external suppliers.